| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Bicheng |

| Certification : | UL, ISO9001, IATF16949 |

| Price : | USD9.99-99.99/PCS |

| Payment Terms : | T/T |

| Supply Ability : | 5000PCS per month |

| Delivery Time : | 8-9 working days |

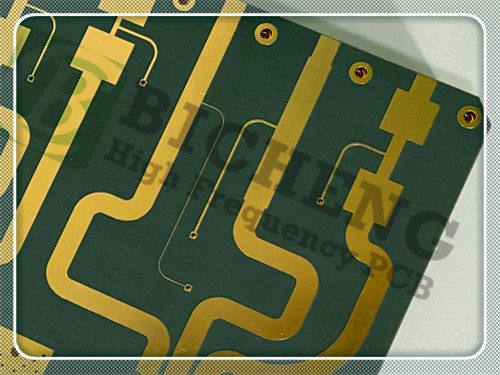

In the rapidly evolving landscape of technology, the demand for high-performance printed circuit boards (PCBs) is continually increasing. The TLY-5 double-Layer Rigid PCB has been introduced as a cutting-edge solution, specifically engineered to meet the rigorous requirements of automotive radar and telecommunications applications. This article delves into the features, benefits, specifications, and applications of the TLY-5 PCB, providing valuable insights for engineers, manufacturers, and decision-makers.

Introduction to TLY-5

The TLY-5 laminate is crafted from lightweight woven fiberglass,

which significantly enhances its dimensional stability compared to

traditional chopped fiber reinforced PTFE composites. This woven

structure provides a mechanically stable laminate, making it

suitable for high-volume manufacturing environments. With a low

dissipation factor, the TLY-5 is particularly well-suited for

automotive radar applications designed to operate at 77 GHz, as

well as for various antennas in millimeter wave frequencies.

Key Features

The TLY-5 PCB boasts several advanced features that set it apart in

the market:

Dielectric Constant: The laminate exhibits a dielectric constant of

2.2 with a tight tolerance of 0.02 at 10 GHz / 23°C. This

consistency ensures reliable signal integrity across a range of

applications.

Loss Tangent: An exceptionally low loss tangent of 0.0009 at 10 GHz

minimizes energy loss, enhancing overall efficiency in

high-frequency operations.

Density: With a specific gravity of 2.19 g/cm3, the material

combines lightweight properties with robust mechanical strength.

Moisture Absorption: The moisture absorption rate is limited to

just 0.02%, ensuring stability and reliability in varying

environmental conditions.

Coefficient of Thermal Expansion (CTE): The CTE values of 26 ppm/°C in the X-axis, 15 ppm/°C in the Y-axis, and 217 ppm/°C in the Z-axis contribute to the thermal stability of the PCB.

Benefits

The TLY-5 PCB provides a multitude of advantages, making it an

excellent choice for various applications:

Dimensionally Stable: The woven fiberglass structure allows for

enhanced mechanical stability, ensuring that the PCB maintains its

dimensions under different conditions.

Lowest Dissipation Factor: This characteristic leads to improved

signal transmission efficiency, making it ideal for high-frequency

applications.

Low Moisture Absorption: The minimal moisture absorption enhances

the durability and performance of the PCB in humid environments.

High Copper Peel Strength: This feature ensures strong

interconnections, contributing to the reliability and longevity of

the PCB.

Uniform Dielectric Constant: Consistent dielectric properties lead to dependable performance across a wide frequency range, essential for precision applications.

PCB Construction and Specifications

This 2-Layer Rigid PCB is constructed with meticulous attention to

detail:

Stackup: The PCB is composed of two copper layers (35 μm each)

surrounding a core of TLY-5 that measures 0.508 mm (20 mil).

Board Dimensions: The dimensions are set at 175 mm x 170 mm, with a

tolerance of ±0.15 mm, allowing for precise integration into

various designs.

Minimum Trace/Space: The specifications allow for a minimum trace

and space of 9/12 mils, accommodating high-density circuit layouts.

Minimum Hole Size: A minimum hole size of 0.3 mm supports a variety

of component types and facilitates versatile design options.

Finished Thickness: The finished board thickness is recorded at 0.6

mm, with an outer copper weight of 1 oz (1.4 mils).

Surface Finish: Immersion gold is applied to ensure excellent

electrical conductivity and protection against environmental

factors.

Silkscreen and Solder Mask: No silkscreen or solder mask is

applied, providing a clean and unobstructed surface for assembly.

Testing: A rigorous 100% electrical testing process is employed prior to shipment, ensuring that each board meets stringent performance criteria.

Quality Assurance

The TLY-5 PCB adheres to IPC-Class-2 standards, which guarantees

high-quality performance and reliability. This commitment to

quality control minimizes the risk of field failures and enhances

customer satisfaction.

Typical Applications

The versatility of the TLY-5 PCB makes it suitable for a wide range

of applications, including:

Automotive Radar: Ideal for advanced driver-assistance systems

(ADAS) and other vehicle safety technologies that require reliable

high-frequency performance.

Satellite/Cellular Communications: Effectively supports

high-frequency communication systems, ensuring stable connections

and data transmission.

Power Amplifiers: Enhances performance in RF applications,

providing the necessary reliability for critical systems.

LNBs, LNAs, LNCs: Effective for low-noise applications in satellite

communications, contributing to improved signal quality.

Aerospace: Meets rigorous standards for reliability and performance

in demanding aerospace applications.

Ka, E, and W Band Applications: Supports cutting-edge technologies

in telecommunications and radar systems.

Conclusion

The TLY-5 2-Layer Rigid PCB represents a significant advancement in

PCB technology, combining high-performance characteristics with

proven reliability and cost-effectiveness. Its robust electrical

properties, excellent dimensional stability, and compatibility with

standard manufacturing processes make it an ideal choice for modern

electronic applications. As the demand for innovative solutions

continues to grow, the TLY-5 PCB stands out as a reliable option

that meets the challenges of today’s sophisticated designs.

Investing in this PCB not only enhances performance but also

ensures long-term satisfaction for engineers and their projects.

|