| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Bicheng |

| Certification : | UL, ISO9001, IATF16949 |

| Price : | USD9.99-99.99/PCS |

| Payment Terms : | T/T |

| Supply Ability : | 5000PCS per month |

| Delivery Time : | 8-9 working days |

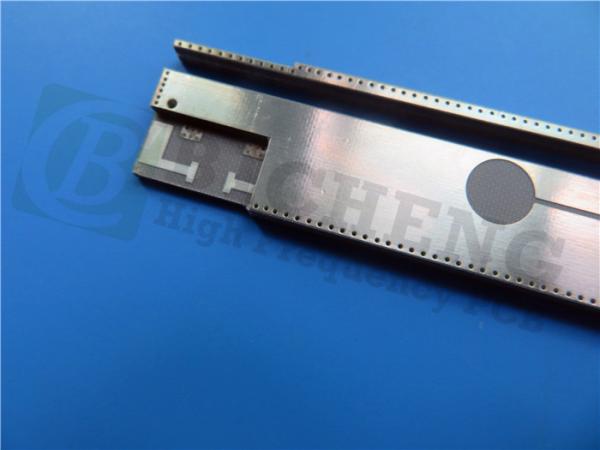

Introducing a newly shipped PCB based on Rogers TMM 13i material. TMM13i substrate is a cutting-edge ceramic thermoset polymer composite designed for high plated thru-hole reliability in strip-line and micro-strip applications. Combining the advantages of ceramic and PTFE substrates, TMM13i offers exceptional performance while maintaining the ease of soft substrate processing techniques.

Key Features:

The TMM13i PCB boasts impressive features that ensure reliable

signal transmission and operational stability:

- Isotropic Dielectric Constant (Dk) of 12.85 +/- .35 ensures

consistent signal propagation.

- Dissipation factor of .0019 at 10GHz minimizes signal loss for

optimal performance.

- Thermal coefficient of Dk of -70 ppm/°K provides excellent

thermal stability.

- Coefficient of thermal expansion matched to copper for reliable

operation.

- Decomposition Temperature (Td) of 425 °C TGA ensures

high-temperature resilience.

- Thermal Conductivity of 0.76W/mk enables efficient heat

dissipation.

- Available in a versatile thickness range of .0015 to .500 inches,

with tight tolerance of +/- .0015".

Benefits:

The TMM13i PCB offers a range of benefits that enhance its

reliability and functionality:

- Mechanical properties resist creep and cold flow, ensuring

long-term durability.

- Resistant to process chemicals, reducing damage during

fabrication.

- Eliminates the need for sodium napthanate treatment prior to

electroless plating.

- Based on a thermoset resin, allowing for reliable wire-bonding.

| Property | TMM13i | Direction | Units | Condition | Test Method | |

| Dielectric Constant,εProcess | 12.85±0.35 | Z | 10 GHz | IPC-TM-650 2.5.5.5 | ||

| Dielectric Constant,εDesign | 12.2 | - | - | 8GHz to 40 GHz | Differential Phase Length Method | |

| Dissipation Factor (process) | 0.0019 | Z | - | 10 GHz | IPC-TM-650 2.5.5.5 | |

| Thermal Coefficient of dielectric constant | -70 | - | ppm/°K | -55℃-125℃ | IPC-TM-650 2.5.5.5 | |

| Insulation Resistance | >2000 | - | Gohm | C/96/60/95 | ASTM D257 | |

| Volume Resistivity | - | - | Mohm.cm | - | ASTM D257 | |

| Surface Resistivity | - | - | Mohm | - | ASTM D257 | |

| Electrical Strength(dielectric strength) | 213 | Z | V/mil | - | IPC-TM-650 method 2.5.6.2 | |

| Thermal Properties | ||||||

| Decompositioin Temperature(Td) | 425 | 425 | ℃TGA | - | ASTM D3850 | |

| Coefficient of Thermal Expansion - x | 19 | X | ppm/K | 0 to 140 ℃ | ASTM E 831 IPC-TM-650, 2.4.41 | |

| Coefficient of Thermal Expansion - Y | 19 | Y | ppm/K | 0 to 140 ℃ | ASTM E 831 IPC-TM-650, 2.4.41 | |

| Coefficient of Thermal Expansion - Z | 20 | Z | ppm/K | 0 to 140 ℃ | ASTM E 831 IPC-TM-650, 2.4.41 | |

| Thermal Conductivity | - | Z | W/m/K | 80 ℃ | ASTM C518 | |

| Mechanical Properties | ||||||

| Copper Peel Strength after Thermal Stress | 4.0 (0.7) | X,Y | lb/inch (N/mm) | after solder float 1 oz. EDC | IPC-TM-650 Method 2.4.8 | |

| Flexural Strength (MD/CMD) | - | X,Y | kpsi | A | ASTM D790 | |

| Flexural Modulus (MD/CMD) | - | X,Y | Mpsi | A | ASTM D790 | |

| Physical Properties | ||||||

| Moisture Absorption (2X2) | 1.27mm (0.050") | 0.16 | - | % | D/24/23 | ASTM D570 |

| 3.18mm (0.125") | 0.13 | |||||

| Specific Gravity | 3 | - | - | A | ASTM D792 | |

| Specific Heat Capacity | - | - | J/g/K | A | Calculated | |

| Lead-Free Process Compatible | YES | - | - | - | - | |

This PCB utilizes a 2-layer rigid PCB stackup, offering a straightforward and adaptable design. The stackup consists of three main components:

1. Copper_layer_1: With a thickness of 35 μm, this layer plays a crucial role in efficient signal conduction. It ensures reliable transmission of electrical signals throughout the PCB, minimizing losses and maintaining signal integrity.

2. Rogers TMM10i Core: This core layer has a thickness of 0.381 mm (15mil) and is made of Rogers TMM10i material. It is specifically chosen for its exceptional electrical properties, providing optimal performance in high-frequency applications. The TMM10i core contributes to signal stability and minimizes any undesirable effects that could hinder the PCB's functionality.

3. Copper_layer_2: Similar to Copper_layer_1, this layer has a thickness of 35 μm. It acts as an additional conductor, supporting consistent signal performance and ensuring effective signal transmission throughout the PCB.

By combining these layers, this PCB achieves a balanced stackup configuration that enables efficient signal conduction, excellent electrical properties, and reliable performance for a wide range of high-frequency applications.

| PCB Material: | Ceramic, Hydrocarbon, Thermoset Polymer Composites |

| Designation: | TMM13i |

| Dielectric constant: | 12.85 |

| Layer count: | Double Layer, Multilayer, Hybrid PCB |

| Copper weight: | 0.5oz (17 µm), 1oz (35µm), 2oz (70µm) |

| PCB thickness: | 15mil (0.381mm), 20mil (0.508mm), 25mil (0.635mm), 30mil(0.762mm), 50mil (1.27mm), 60mil (1.524mm), 75mil(1.905mm), 100mil (2.54mm), 125mil (3.175mm), 150mil (3.81mm), 200mil (5.08mm), 250mil (6.35mm), 275mil (6.985mm), 300mil (7.62mm), 500mil (12.7mm) |

| PCB size: | ≤400mm X 500mm |

| Solder mask: | Green, Black, Blue, Yellow, Red etc. |

| Surface finish: | Bare copper, HASL, ENIG, OSP, Immersin tin, Immersion silver, Pure gold plated etc.. |

PCB Specifications:

- Board dimensions: 90mm x 65mm=1PCS, +/- 0.15mm

- Minimum Trace/Space: 7/7 mils for intricate circuit designs.

- Minimum Hole Size: 0.5mm for versatile component placement.

- No Blind vias for simplified manufacturing and structural

integrity.

- Finished board thickness: 0.5mm for durability and compactness.

- Finished Cu weight: 1oz (1.4 mils) outer layers for excellent

conductivity.

- Via plating thickness: 20 μm for reliable electrical connections.

- Surface finish: Immersion Gold for enhanced conductivity and

protection against oxidation.

- Top and Bottom Silkscreen: No for a clean and unobstructed PCB

surface.

- Top Solder Mask: Green for added protection.

- Bottom Solder Mask: No for a clean and unobstructed PCB surface.

- 100% Electrical test used prior to shipment for quality

assurance.

PCB Statistics:

- Components: 17

- Total Pads: 47

- Thru Hole Pads: 31

- Top SMT Pads: 16

- Bottom SMT Pads: 0

- Vias: 10

- Nets: 3

Artwork and Quality:

This PCB is supplied with Gerber RS-274-X artwork, meeting the IPC-Class-2 quality standard. It is available worldwide, ensuring accessibility for various applications.

Typical Applications:

The TMM13i PCB is suitable for a wide range of applications,

including:

- RF and microwave circuitry

- Power amplifiers and combiners

- Filters and couplers

- Satellite communication systems

- Global Positioning Systems (GPS) Antennas

- Patch Antennas

- Dielectric polarizers and lenses

- Chip testers

Discover the dependability and efficiency offered by the TMM13i Isotropic Thermoset Microwave PCB, opening up a whole new range of opportunities for your electronic projects.

|