| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Bicheng |

| Certification : | UL, ISO9001, IATF16949 |

| Price : | USD9.99-99.99/PCS |

| Payment Terms : | T/T |

| Supply Ability : | 5000PCS per month |

| Delivery Time : | 8-9 working days |

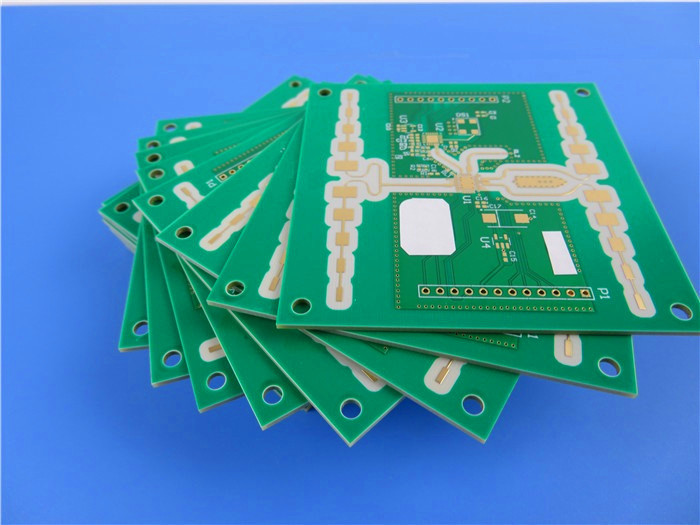

Introducing a High-Performance PCB on CLTE-XT. Rogers CLTE-XT laminates are composite materials that combine micro-dispersed ceramic filler, PTFE, and woven fiberglass reinforcement. Intended to deliver exceptional performance, CLTE-XT offers the lowest insertion loss and highest dimensional stability in its class. Let's explore the remarkable features and benefits of this cutting-edge PCB:

Features:

Dielectric Constant (DK) range of 2.79 to 2.94 at 10GHz, 23°C @ 50%

RH

Dissipation Factor of 0.0010 at 10GHz, 23°C @ 50% RH

X-axis CTE of 12.7ppm/°C, Y-axis CTE of 13.7ppm/°C, Z-axis CTE of

40.8ppm/°C

Decomposition Temperature (Td) of 539°C

Thermal Coefficient of Dielectric Constant of -8ppm/°C

Tightest dielectric constant tolerance in the CLTE family (+/- .03)

Low Moisture Absorption of 0.02%

Benefits:

High plated through-hole reliability

Consistent performance across different production lots

Reduced circuit losses while maintaining dimensional stability

Stable dielectric constant under temperature variations, reducing

stress on ceramic active devices

| Properties | CLTE-XT | Units | Test Conditions | Test Method | |

| Electrical Properties | |||||

| Dielectric Constant | 2.94 | - | 23˚C @ 50% RH | 10 GHz | IPC TM-650 2.5.5.5 |

| Dissipation Factor | 0.0010 | - | 23˚C @ 50% RH | 10 GHz | IPC TM-650 2.5.5.5 |

| Dielectric Constant (design) | 2.93 | - | C-24/23/50 | 10 GHz | Microstrip Differential Phase Length |

| Thermal Coefficient of Dielectric Constant | -8 | ppm/˚C | -50°C to 150°C | 10 GHz | IPC TM-650 2.5.5.5 |

| Volume Resistivity | 4.25x10⁸ | Mohm-cm | C-96/35/90 | - | IPC TM-650 2.5.17.1 |

| Surface Resistivity | 2.49x10⁸ | Mohm | C-96/35/90 | - | IPC TM-650 2.5.17.1 |

| Electrical Strength (dielectric strength) | 1000 | V/mil | - | - | IPC TM-650 2.5.6.2 |

| Dielectric Breakdown | 58 | kV | D-48/50 | X/Y direc- tion | IPC TM-650 2.5.6 |

| PIM (For antenna only) | - | dBc | - | 50 ohm 0.060" | 43dBm 1900 MHz |

| Thermal Properties | |||||

| Decomposition Temperature (Td) | 539 | ˚C | 2hrs @ 105˚C | 5% Weight Loss | IPC TM-650 2.3.40 |

| Coefficient of Thermal Expansion - x | 12.7 | ppm/˚C | - | -55˚C to 288˚C | IPC TM-650 2.4.41 |

| Coefficient of Thermal Expansion - y | 13.7 | ppm/˚C | - | -55˚C to 288˚C | IPC TM-650 2.4.41 |

| Coefficient of Thermal Expansion - z | 40.8 | ppm/˚C | - | -55˚C to 288˚C | IPC TM-650 2.4.41 |

| Thermal Conductivity | 0.56 | W/(m.K) | - | z direction | ASTM D5470 |

| Time to Delamination | >60 | minutes | as-received | 288˚C | IPC TM-650 2.4.24.1 |

| Mechanical Properties | |||||

| Copper Peel Strength after Thermal Stress | 1.7 (9) | N/mm (lbs/ in) | 10s @288˚C | 35 μm foil | IPC TM-650 2.4.8 |

| Flexural Strength (MD, CMD) | 40.7, 40.0 (5.9, 5.8) | MPa (ksi ) | 25˚C 3˚C | - | ASTM D790 |

| Tensile Strength (MD, CMD) | 29.0, 25.5 (4.2, 3.7) | MPa (ksi ) | 23C/50RH | - | ASTM D638 |

| Flex Modulus (MD. CMD) | 3247, 3261 (471, 473) | MPa (ksi ) | 25C 3C | - | ASTM D790 |

| Dimensional Stability (MD, CMD) | -0.37, -0.67 | mm/m | 4 hr at 105˚C | - | IPC-TM-650 2.4.39a |

| Physical Properties | |||||

| Flammability | V-0 | - | - | C48/23/50 & C168/70 | UL 94 |

| Moisture Absorption | 0.02 | % | E1/105+D24/23 | - | IPC TM-650 2.6.2.1 |

| Density | 2.17 | g/cm³ | C-24/23/50 | - | ASTM D792 |

| Specifc Heat Capacity | 0.61 | J/g˚K | 2 hours at 105˚C | - | ASTM E2716 |

| NASA Outgassing | 0.02 / 0.00 | % | TML/CVCM | ASTM E595 | |

PCB Stackup:

2-layer rigid PCB

Copper_layer_1 - 35 μm

Rogers CLTE-XT Core - 0.762 mm (30mil)

Copper_layer_2 - 35 μm

The PCB construction details for this High-Performance PCB are as follows:

The board dimensions are 42.91mm x 108.31mm, with a tolerance of +/- 0.15mm for a single piece. The minimum trace width and spacing are 5 mils and 7 mils, respectively. The minimum hole size is 0.3mm, ensuring compatibility with a wide range of components.

The board does not include any blind vias, simplifying the manufacturing process. The finished board thickness is 0.8mm, providing a balance between durability and space constraints. The outer layers have a copper weight of 1oz (equivalent to 1.4 mils), ensuring good electrical conductivity and heat dissipation.

The via plating thickness is 20 μm, ensuring reliable connections throughout the board. The surface finish is immersion tin, which provides a protective coating and enhances solderability. The top silkscreen is printed in black, allowing for clear component labeling and identification. The bottom silkscreen is not included in this PCB design.

The top and bottom solder masks are not applied in this particular PCB. However, this can be customized based on specific requirements. Prior to shipment, a 100% electrical test is performed on each PCB to ensure its functionality and adherence to quality standards.

In terms of PCB statistics, this PCB includes a total of 21 components. There are 68 pads in total, with 41 being thru-hole pads and 27 being top surface mount technology (SMT) pads. There are no bottom SMT pads in this design. The PCB features 65 vias, facilitating connections between different layers. The design encompasses 3 nets, ensuring proper signal routing and integrity.

The quality standard for this PCB is IPC-Class-2, which guarantees reliability and adherence to industry standards. The artwork format used for this design is Gerber RS-274-X, a widely accepted format in the PCB manufacturing industry. The CLTE-XT High-Performance PCB is available worldwide, ensuring accessibility for engineers and manufacturers across different regions.

| PCB material: | Ceramic/PTFE Microwave Composite |

| Designation: | CLTE-XT |

| Dielectric constant: | 2.94 |

| Layer count: | Sinlge-sided PCB, Double-sided PCB, Multi-layer PCB, Hybrid PCB |

| Dielectric thickness: | 5.1mil(0.130mm), 9.4mil (0.239mm), 20mil (0.508mm), 25mil(0.635mm), 30mil(0.762mm), 40mil(1.016mm), 45mil(1.143mm), 59mil(1.499mm), 60mil(1.524mm) |

| Copper weight: | 1oz (35µm), 2oz (70µm) |

| PCB size: | ≤400mm X 500mm |

| Solder mask: | Green, Black, Blue, Red, Yellow etc. |

| Surface finish: | Immersion gold, HASL, Immersion silver, Immersion tin,ENEPIG, Bare copper, OSP, Pure gold plated etc.. |

Some Typical Applications:

Advanced Driver Assistance Systems (ADAS)

Patch Antennas

Phased Array Antennas

Power Amplifiers

Ground-based and airborne communications and radar systems

|